People-Centered Automation: Safer, Faster, Happier

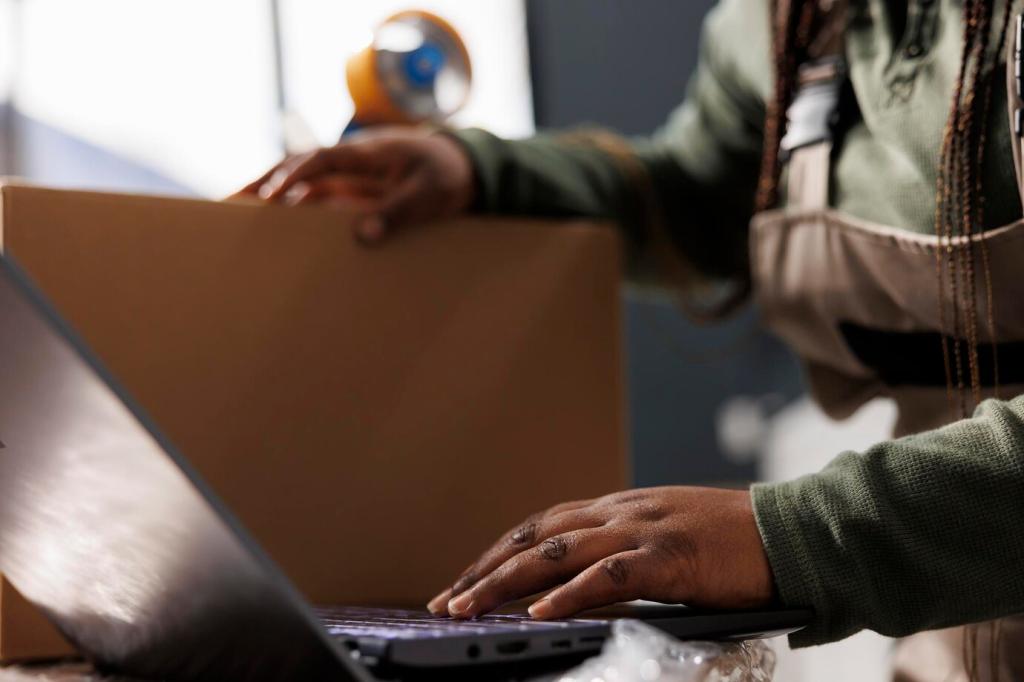

Run quick design sessions on cart height, light placement, and RF workflows. Operators catch friction points that managers miss. Share one improvement suggested by your crew that paid off immediately, and recognize them here to build momentum for the next change.

People-Centered Automation: Safer, Faster, Happier

Deliver five-minute modules at shift start with simple job aids near stations. Reinforce key steps with visuals and quick quizzes. If micro-learning reduced ramp-up time in your facility, comment with your favorite module topic and how you keep it fresh.