Chosen theme: Automation Tools for Streamlining Warehouse Inventory. Step into a smarter, calmer warehouse where data flows, errors shrink, and teams finally breathe. We’ll explore tools, tactics, and real stories that turn chaos into clarity—then invite you to share your wins and questions.

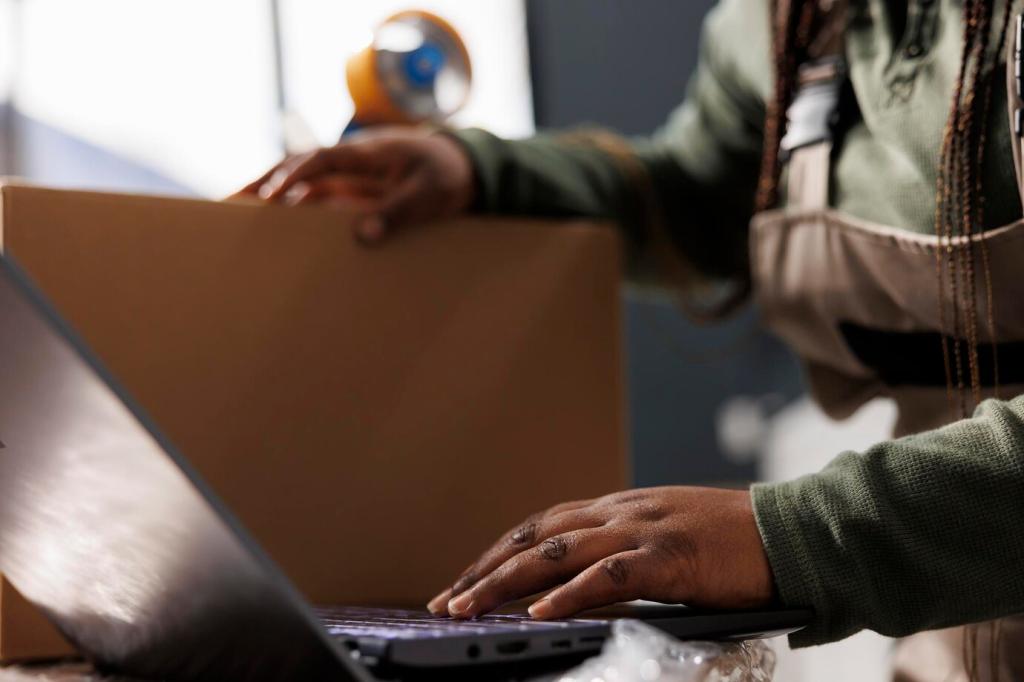

Why Automation Tools Matter in Warehouse Inventory

From clipboards to cloud clarity

Many warehouses still rely on paper counts and tribal knowledge. Moving to scanners, mobile apps, and a modern WMS replaces guesswork with proof, timestamped by every scan. Share your current process—we’ll help map a gentle upgrade path that respects people and budgets.

Error reduction is a growth engine

Inventory mistakes ripple into missed shipments, returns, and unhappy customers. Automation tools reduce human error, standardize tasks, and create reliable feedback loops. Comment with your biggest pain point, and we’ll suggest a low-risk pilot to validate improvements without disrupting daily operations.

Real-time visibility beats firefighting

When counts update instantly, teams spend less time hunting and more time fulfilling. Live dashboards show where stock actually is, not where it was last week. Want a sample dashboard layout? Subscribe and we’ll send a practical template built from real warehouse use cases.

Warehouse Management Systems that orchestrate flow

A solid WMS directs receiving, putaway, picking, counting, and shipping. It enforces process steps, captures data, and integrates with ERP. If you’re choosing a WMS, list your top three workflows in the comments, and we’ll share evaluation criteria that matter in real life.

RFID for speed and non-line-of-sight accuracy

RFID reads multiple tags at once without needing a direct line of sight, making cycle counts and audit checks dramatically faster. One distributor cut weekly count time by 70% after deploying handheld readers. Curious about tag costs? Ask below and we’ll break down typical ranges.

Smart Hardware: AMRs, Drones, and Industrial IoT

AMRs that carry, count, and coordinate

Autonomous Mobile Robots reduce walking time by shuttling totes between zones and guiding associates to the next best task. Integrated with WMS tasks, they boost throughput without expanding footprints. Thinking about AMRs? Comment with aisle widths and payload needs; we’ll suggest fit considerations.

Drones for rapid, safer cycle counts

Inventory drones scan upper racks without lifts, improving safety and speed. A mid-market wholesaler reported weekend counts done by Sunday afternoon, not Wednesday. Want to know about lighting and barcode contrast for drone scanning? Ask below and we’ll share a proven checklist.

IoT sensors that turn racks into data sources

Temperature, humidity, vibration, and location sensors create context around every item. Alerts flag risks before products spoil or parts go missing. Considering cold-chain visibility or high-value SKUs? Subscribe for a practical guide to calibrating thresholds and interpreting the signals that matter.

Human-Centered Automation: Pick-to-Light, Voice, and Wearables

LED prompts eliminate guesswork, highlight locations, and confirm quantities visually. Operators learn in hours, not weeks. A story we love: a team cut mis-picks in peak season by double digits after a two-day rollout. Curious about retrofitting? Comment and we’ll outline wiring and zone planning tips.

Data and Integration: APIs, Analytics, and Forecasting

Modern APIs reduce spreadsheet gymnastics and late-night file drops. With events and webhooks, orders, counts, and shipments sync in near real time. Post your current integrations, and we’ll recommend a minimal, high-impact interface to prove value quickly without boiling the ocean.

Data and Integration: APIs, Analytics, and Forecasting

Dashboards should surface exceptions, not drown teams in charts. Highlight stockouts, aging inventory, slotting heatmaps, and late picks. Want a starter metrics pack? Subscribe to receive our KPI card designs with thresholds, colors, and alert rules tuned for real warehouse rhythms.

Pilot, iterate, and scale responsibly

Pick a contained process—like cycle counts in one zone—define targets, and run a timeboxed pilot. Document lessons, adjust processes, and train champions. Comment with your pilot candidate, and we’ll help shape hypotheses, timelines, and success criteria that sponsors can rally behind.

KPIs that actually move the needle

Track inventory accuracy, mis-pick rate, lines per hour, dwell time, and dock-to-stock. Add safety and training time to reflect real-world performance. Want a ready-to-use KPI sheet? Subscribe and we’ll send a simple template with formulas and benchmark ranges to start conversations.

Change management that respects your people

Automation should feel like help, not surveillance. Communicate the why, involve operators early, and celebrate quick wins. Offer micro-learning and peer coaching. Share your team’s concerns anonymously, and we’ll suggest messaging and training formats that build trust and sustain momentum.